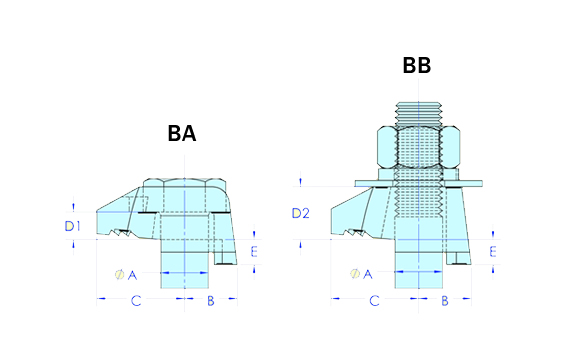

BeamClamp Components Type BA and BB

- Jump To:

- Photos/Drawings

- Product FAQs

- Technical Specs

Overview

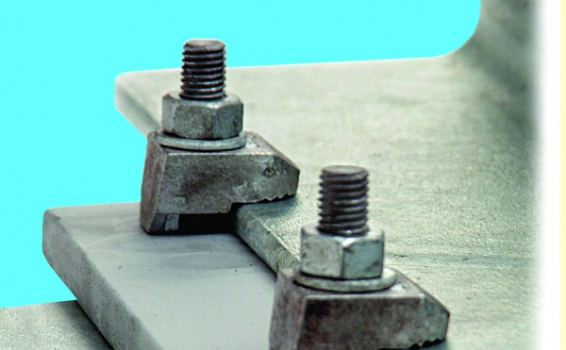

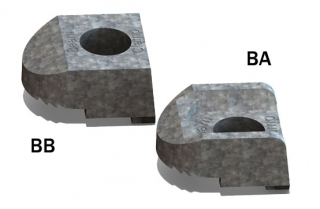

The types BA and BB are commonly used in pairs to clamp two steel sections together. The type BA has a recessed top to grip the head of a grade 8.8 setscrew or bolt. This allows a nut and washer to be tightened down on to the flat top of the BB using one tool only. Both clamps are available with three tail lengths, 1, 2 or 3 (dim E). This should be as near to the thickness of steel it is clamping on or slightly less if an exact match is not possible. Packing pieces BF1, BG1 and BH1 can be used in combination with the tail length to achieve a match to the steel flange. BA and BB types are suitable for parallel flanges and flanges up to 8 degrees taper. They can also be used on their own if one piece of the steelwork has been pre-drilled. To simplify the selection of tail lengths and packing pieces, please see our selection charts in our resources area. To see how the BA and BB Clamps are commonly used please view this video.

- Hot Dip Galvanized to BS EN ISO 1461

- Manufactured from Ductile Iron to BS EN 1563

- 5 to 1 Factor of Safety

- Lloyds Register approved

- DIBt approved

Product FAQs

What is the recess in the BA used for?

Answer: The recess is used to captivate a hexagon head of a bolt or nut to stop it spinning and allow tightening to take place by using one wrench only.

Why do the BA/BB clamps have specific tail lengths?

Answer: Our BA/BB Clamps have a specific tail length that are given as dimension E in our technical information. The tail length is used in combination with the thickness of our packing shims to ensure the clamp can connect as close to 90 degrees to the steel flange as possible. Our BA and BB Clamps have three tail lengths 1,2 and 3. A calculation chart is available in our catalog or in our resources section under “Specifying Beamclamp”, alternatively if you need assistance please contact our technical department.

Do I always have to use the BA and BB together?

Answer: No. The BA or BB can be used on their own when only clamping to one steel section. In this situation the BA is generally used to ease installation as tightening can be achieved using one tool only. A BB can be used it just means two wrench’s are required for installation.

What packing pieces can I use with the BA/BB Clamps?

Answer: The BF1, BG1 and BH1 are all designed to work with the BA/BB Clamps. The packings are used to ensure the clamp is secured as close to 90 degrees onto the steel as possible.