BeamClamp Components Type BK1

- Jump To:

- Photos/Drawings

- Product FAQs

- Technical Specs

Overview

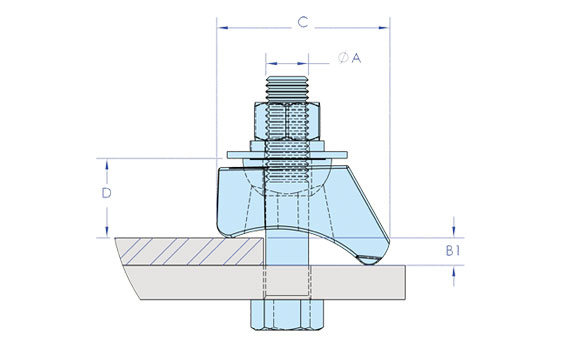

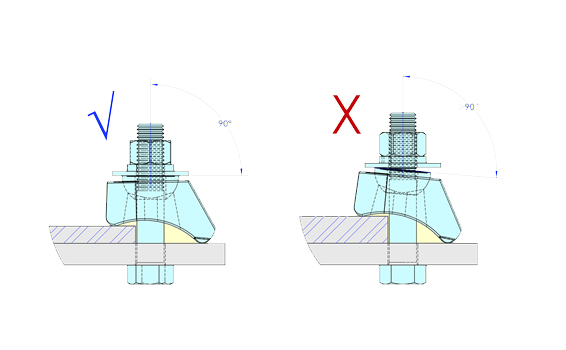

The BK1 is a self adjusting clamp that consists of two parts. The main body provides a recess to allow a hemispherical washer to be seated. This allows the body to adjust between a specified clamping range and as the washer rotates it provides a flat surface for a nut. This mechanism makes the product suitable for clamping to tapered steel of up to 15 degrees. It is also extremely useful for projects where the thickness of steel may vary. The M08, M10 and M12 versions feature a tab at the back edge that can be located in the open ends of strut products, both aiding installation and preventing rotation once installed. Should the maximum clamping range be exceeded, our BF2 and BG2 packers can be used to increase it. See this video to see an example of the BK product in action.

- Hot Dip Galvanized BS EN ISO 1461

- Manufactured from Ductile Iron to BS EN 1563

- 5 to 1 Factor of Safety

- Lloyds Register approved

- Self adjusting body style

Product FAQs

What is the benefit of using a BK Clamp?

Answer: The BK Clamp is self adjusting so it can connect to a range of steel thicknesses without the need for packing pieces (See ranges B1 and B2). The washer in the middle rotates to allow the nut or bolt head to be clamping at 90 degrees to the steel.

Can I use packing pieces with BK Clamps?

Answer: Yes. Once you have reached the maximum clamping range of the BK Clamp (Dim B1) then you can use either our BF2 or BG2 long packing pieces. These packers are slightly longer to support the back of the BK Clamp.

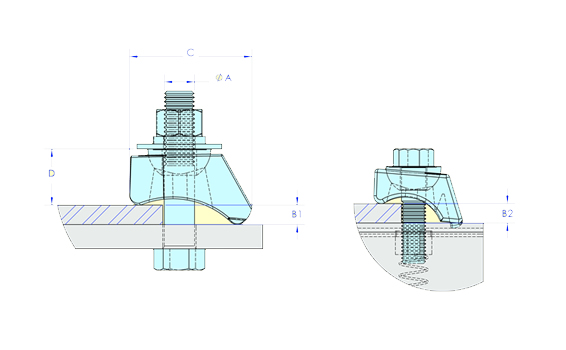

Why does the BK have two clamping ranges B1 and B2?

Answer: B1 is for when the clamp is used on a flat surface such as a location plate and B2 is for when the clamp is used with Strut products or within slots.

Why does the BK in M08, M10 and M12 have a tab on the back of it?

Answer: This feature allows the BK to locate into Strut products or slots and stops it from rotating out once it has been tightened into position.